Our Products

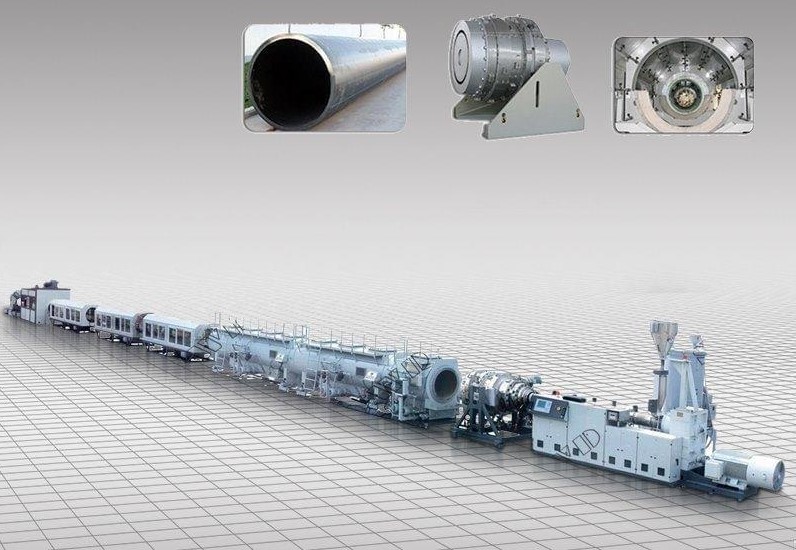

HDPE / PPR Pipe Extruder Plant (HDPEEX)

___

- Pipe Extrusion products are manufactured in accordance with the predefined industry. Backed by the expertise of an adept team, we are one of the leading manufacturers and supplier of Pipe Extrusion Machinery.

- For traditional production lines for PVC, PE, PP (mono or multilayer) or special custom made solutions, Infinite India provides a specialized project management unit equipped to deal with a wide range of requests.

- Always keeping in mind the economic optimization of the plant and production, the company can give assistance at any step of the project; from the feasibility study and machinery planning to the start-up and after sales support.

HDPE / PPR Extruder Range :

- 50 mm with 32:1 L:D to 90 mm with 32:1 L:D Ratio

- Output Ranges from 80 Kg/hr to 900 Kg/hr

Die Head :

- 20 mm to 315 mm

- Single Layer & Multilayer

Vacuum Tank :

- 110 mm to 315 mm

- MS / SS Material to Choose

Haul-Off :

- 20 mm to 315 mm

- 2 Belt, 4 Belts, 6 Belts

Coiler :

- 20 mm to 110 mm

|

KEY FEATURES OF SCREW BARREL :

|

|

FEATURES :

|

|

|

|

TECHNICAL FEATURES :

|

ADVANTAGES :

|

|

TECHNICAL FEATURES :

|

|

ADVANTAGES :

|

|

|

ADVANTAGES AND KEY FEATURES :

|

|

TECHNICAL FEATURES :

|

|

ADVANTAGES :

|

|

Work In progress

Contact Us: +91 7383852878

Company Address

Ahmedabad,

Gujarat, India.

Phone Numbers

Mobile: +91 7383852878